When looking at examples of interagency cooperation, Charlotte County, Florida, has a standard that would make many others jealous. As an aviation unit, Charlotte County’s mission profile is more significant than many more prominent agencies with more aircraft. Yet, somehow, between the county’s Sheriff’s Office, Fire Department, and Mosquito control agency, they still find constant opportunities to better serve the county through their aviation unit.

Chief Pilot Shane Englauf, who heads the unit, has continued to rise to the occasion every time a challenge is given. From the agency initially only providing law enforcement operations to now, years later encompassing law enforcement missions and many successful firefighting missions, plus conducting all of the county’s aerial applications to eradicate mosquitos each season.

The increase in capability and aircraft is a testament to the cooperation between Englauf and other agency heads committed to making the operation work, such as Charlotte County Public Safety Director and Fire Chief Jason Fair.

“The reason we got more involved in doing more with the two agencies together was the total commitment from Shane [Englauf] and his team towards making it work. Our cooperation has proven to be a force multiplier for our agency and continues to provide benefits for the county,” said Fair.

One of the things fire departments do very well is provide mutual aid assistance to other agencies. Fair explained that mutual aid is handled through requests made as part of Florida’s State Emergency Response Plan. Charlotte County helicopters have often been asked to assist on several large fires. A fire in August of 2020 quickly turned into a raging inferno involving over 3500 rental cars at the Fort Myers airport. Englauf and his team were activated to assist in Lee County, located to the south of Charlotte County, spending several hours fighting the large blaze along with ground firefighters.

Englauf mentioned that they struggled with cars exploding when hit by water from the aircraft in a meeting between the two on capabilities and potential improvements after that fire. He suggested that they avoid fighting ground fires by using class A firefighting foam, which is water injected with the foaming agent as it is dispersed. After that conversation, it was decided to investigate the potential cost of designing and installing a foam injection system on the agency’s primary firefighting helicopter, a UH-1H Huey that contained a 350-gallon water tank.

Inventing New Technology

While there are many foam injection systems in the aerial firefighting world, purchasing an externally manufactured system would have been cost-prohibitive to accomplish Charlotte County Fire’s mission. So Englauf turned the task over to his internal team of A&P mechanics and avionics specialists Dan IJpkemeule and Nathan Huck, who also serve as crew chiefs in the field when the helicopters are tasked missions.

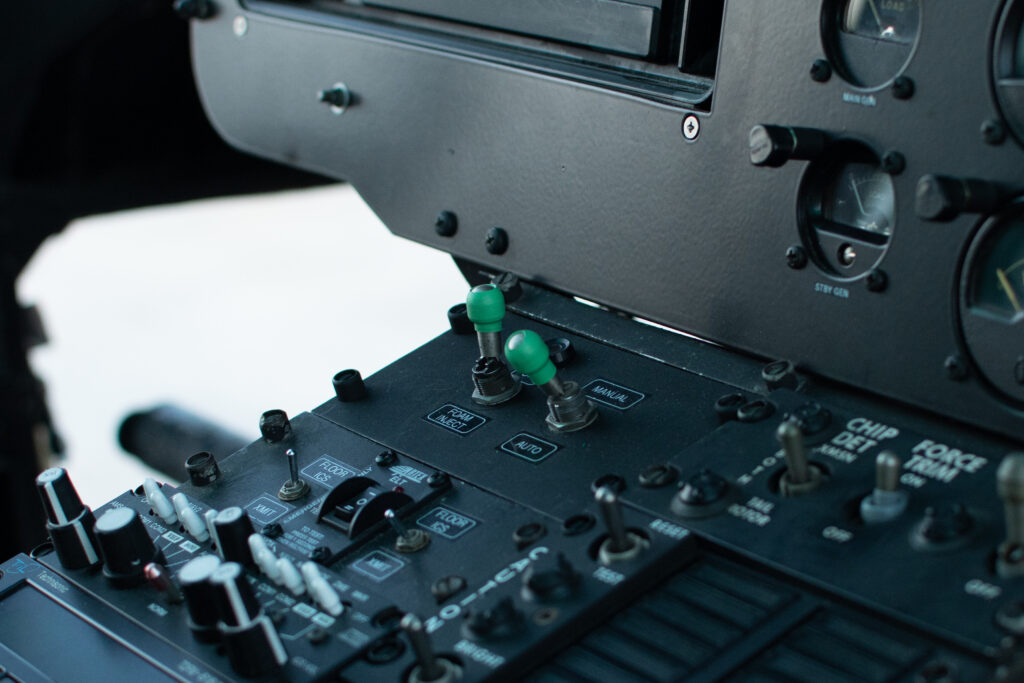

Huck took primary responsibility for the design and construction of the system. The system took approximately two months to complete, from design to functional installation and testing. Huck designed the system using a 30-gallon Jazz Racing fuel cell tank to hold the type A firefighting foam and fabricate a relatively simple electronic relay system with switches on the switch panel and on the cyclic to inject foam into the water tank manually. The system will also switch it to automatically mix in foam agent with every tank fill, with the tank capable of adding foam to 60 tank loads before filling.

The pump used to inject the foaming agent into the tank is a Marco pump that, incidentally, is the same pump used by the county for mosquito control operations. Deciding to use a proven product was a no-brainer for Huck. The pump had already proven its worth in operational fire use and did not suffer from the clogging reported by many other options used in the field.

Huck thought out everything about the tank’s design thoroughly, including the pickup location for the hose attachment being placed on the bottom rear of the tank. Huck’s methodology for that kind of placement was to ensure that as much foam mixer as possible can empty from the tank, and based on the 3-4º bank angle to the rear the UH-1H hovers at, that would allow the tank a little extra slope to drain into the water tank when almost empty.

Because the agency is multi-mission capable, Huck also designed the system to be modular and easily removable. He describes the ability to remove the tank system with a couple of wrenches.

“If we need to remove it, I need a ratchet with an extension to get to the hardware in the back, which is just two bolts on the backside and two nuts on the front side, six screws on that plate, and then a wrench to pull the fitting and then the counterpoint comes up. And then you have your whole cockpit back to moving water supplies or people or whatever you want in about 5 minutes.”

Huck also explained that the design and build were based not only on ease of installation and removal but also on safety through a reduced workload. While there is still an ability to inject foam if the need arises manually, the system is designed to be a completely hands-free operation in the fireground, leaving the pilot to concentrate on picking up and dropping water and other associated tasks during flight.

The most surprising thing to note about the design and build of this specialized system that provides the significant benefit that a foam injection system does is the cost. Huck stated that, including some specialized tools that needed to be purchased for the project, the in-house team managed to design, build and install the system for just over two thousand dollars, which even surprised Fair and his team. Due to the complexity of developing a plan from the ground up, they expected it to be much more than what it eventually cost.

As seen in previous features in AerialFire and our sister publication AgAir Update on the Charlotte County Sheriff’s aviation unit, Charlotte County has proven time and time again that they are far from a ‘standard’ model aviation unit. The unit and its staff continue to think outside the box to find sometimes simple solutions to complex problems that have continued to benefit the citizens of Charlotte County.