By Ryan Varjassy

The NDN-6 Fieldmaster was the brainchild of British aviation legend Nigel Desmond Norman starting back in the mid 1970's. Desmond and his college friend and business partner, John Britten, formed a relationship starting in the 1950's at the De Havilland Technical School where they were both studying aircraft design. In 1954 the two built their first aircraft called the BN1F which was a 36hp ultralight.

The aircraft itself was was a failure from a sales perspective but it did supply them with a third partner, Jim McMahon. Together they formed Crop Culture Aerial which became extremely successful and along with this new partnership came the early stages of the rotary atomizer spray nozzle.

Britten-Norman was formed as a company that specialized as ag operators and supplied ag conversions of Tiger Moths for export to New Zealand. They had taken over development and sales of spraying equipment, most notably the Micronair Rotary Atomizer, and at one point John and Desmond operated a fleet of approximately 80 aircraft. The need to consider a replacement ag plane resulted in a partnership with Leyland Snow from Texas. Britten-Norman acquired a 1/3 share of Snow Aeronautical Corp. and when the company was sold to Rockwell it provided Britten-Norman with the funds to chase their dreams of designing and building their own aircraft. Their idea was to build a small island hopping passenger plane. So after selling off their shares of Crop Culture to the other Board members in 1963, their efforts were put forth into the development of the Britten-Norman Islander which made it's maiden flight in June of 1965 after only nine months of development. The factory was based at Bembridge on the Isle of Wight (IOW) off the south coast of the UK and the small island would remain the home of Desmond's aviation career for years to come.

Over the years Desmond was involved with numerous other businesses and projects but in 1971 Britten-Norman went into liquidation and was purchased by Fairey Aviation in 1972. Desmond would stay on as the managing director until 1976 when he formed his own aviation company, NDN Aircraft Ltd.

The next few years would see the development 3 aircraft:

- NDN Firecracker/Turbo Firecracker – A two place military trainer

- NDN-6 Fieldmaster – Agricultural / Firefighting aircraft

- NAC-1 Freelance – A folding wing 4 place civil aircraft

The NDN-6 Fieldmaster took Desmond back to his ag aviation roots and his design of the aircraft was truly years ahead of it's time. He wanted a modern ag aircraft that pushed the boundaries of what was already being manufactured...and push the limits he did. The aircraft included the following innovations:

- designed from the beginning to have a Pratt & Whitney PT6A-34 750 HP turboprop and could be easily be upgraded to the larger PT6A-65 1250 HP engine if desired

- integral titanium 625 gallon hopper as part of the structural airframe

- aerofoil ailerons and flaps with spray booms built into the internal structure

- tricycle landing gear to aid in ground visibility and the training of new pilots on the type as most pilots are trained on a tricycle configuration

- standard dual cockpit with optional controls for training or a rear seat observer/spotter

- glass canopy for excellent visibility Options included the following:

- firebombing drop gate

– 40 or 80 nozzle option

- Transland spreader

- Micronair Rotary Nozzles (8), Micronair Flow-meter and RPM indicator

- Automatic Flagman

- lighting packages for navigation, instruments, strobe, beacon and retractable working lights both forward and tip mounted for turning

- IFR instruments

- heat and air conditioning

- 2 speed windshield wiper and washer system

The Fieldmaster appeared to be a state of the art ag aircraft or initial attack aerial firefighter with every option possibly available.

After a few years of initial concept work, senior/chief designer Bill Combs had the plans for the new aircraft and work began at the Sandown hangar. Foreman John Cox and his dog Trixi ran the small factory and the aircraft began to take shape. With a talented staff of machinists, sheet metal workers, fitters and engineers, the Fieldmaster was completely built by hand from raw materials assembled in the tiny hangar. An engineering sample was produced as well as all the assembly jigs, and the first flight worthy airframe was created after that.

In November 1981 the aircraft was rolled out of the hangar unofficially and it dwarfed the other aircraft at the small airfield. Desmond performed the first flight on December 17, 1981 at Sandown Airfield on the Isle of Wight and as the story goes, he was wearing his traditional pinstriped suit and set out to put the aircraft through its paces. A short flight was originally planned but the flight time gradually grew and grew without Desmond landing at the airfield. After approximately 30 minutes he finally landed unscathed and promptly stated that he could not make the aircraft turn with any real authority so he had to make a large loop in order to get back to the airfield. The landing was less than spectacular also as the nose wheel failed to straighten as it was anticipated to and the aircraft plowed a trench down the grass strip with the crooked nose wheel. The aircraft was subsequently dug out and towed by a tractor back to the hangar where they got to work fixing the turning problems. The aircraft had been designed with inboard ailerons and outboard flaps, unfortunately the German WW2 design simply did not work so it was changed back to the traditional outboard ailerons and inboard flaps. The NDN Fieldmaster, G- NRDC, got its registration from the project sponsor National Resource Development Corporation and she would make her public debut at the Farnborough in February 1982 and then again at the Farnborough 50th Anniversary SBAC in September 1982,

Test flying and upgrades continued through 1983, 1984 and 1985 leading up to a new production factory being built in Cardiff, Wales with support from the Welsh Development Agency. On July 22, 1985 NDN officially moved to Cardiff and at the same time the name was changed from NDN to NAC (Norman Aeroplane Co.). The factory was staffed and preparations for production of the NAC-6 Fieldmaster were being finalized. Many notable hires were made at this time from production line workers to electrical, airframe and engine engineers.

NAC continued using the original aircraft, NRDC, for testing purposes by doing crop dusting tests in Lelystad, Holland (the Netherlands) for Heyboer BV, working alongside Turboprop Thrush aircraft and Miller Aerials Turboprop Ag-Cats. At this time they were testing and using the Micronair systems mounted to traditional drop booms as opposed to its internal booms as the rotary atomizers could not be adapted to the internal boom system. They were also extensively testing the aircraft for firefighting

roles during this time and had developed a water boom/scoop that would allow the aircraft to refill with water by skimming the surface with the boom lowered beneath and aft of the fuselage at about 10 feet above the water. The water boom was operated by the rear seat spotter using a hand crank attached to a steel cable. Vic Osborne did much of the back seat work during this testing phase and says cranking that boom up and down was an awful experience and that his arm would go numb from raising the boom and recalls wondering why they didn't set it up with an electric winch. Vic also did photo and video work for the boom testing and fire drops from the NAC Freelance aircraft ( a small 4 place general aviation plane with folding wings about teh size of a Cessna 172) with Desmond at the controls. The back seater also was a lookout for watercraft and debris in the water while on the water scooping passes as the pilot was solely concentrating on keeping the boom scoop planted firmly in the water, adjusting trim and airspeed as the hopper filled. The filling sequence would take up to 1min 30 seconds as long as the boom wasn't skipping off the water but the pilots would only keep the boom in the water for 15 to 20 seconds at a time due to the high level of concentration needed. The system did work but it was never implemented for commercial use and testing was ceased.

Years later, Neville Dunn of Dunn Aviation in Western Australia would travel to Sandown to look at the water scooping boom to see if he could somehow make a version of it work in their operations. It is unknown at this time if they ever tested the system but maybe Neville can shine some light on that some day.

The production line at Cardiff was moving along and in early 1987 the first production aircraft was nearing completion. G-NACL would be the first aircraft produced under the new NAC company name and on April 28, 1987 they received the type certificate from the UK CAA (Civil Aviation Authority). On the same day, NACL performed it's first flight with the prototype, NRDC, flying along in formation with Desmond Norman and test pilot Peter Phillips at the controls. NACL flew in primer as Desmond did not want to waste the cost of a new paint-job in case of an accident.

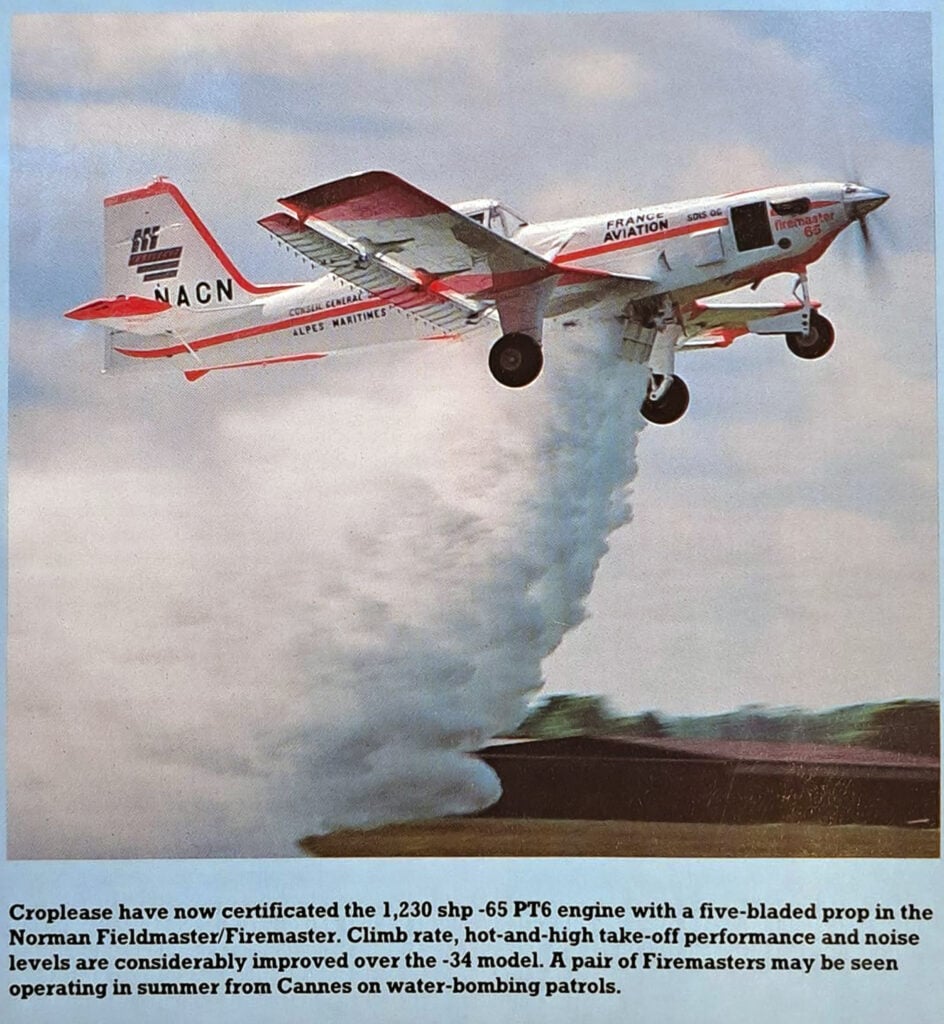

Through May and June of 1987, NACM & NACN were completed and flight certified. Desmond signed a lease firefighting contract to France Aviation Conseil General Des Alpes Maritimes in Cannes in the South of France for their summer firefighting season. All three completed production aircraft were dispatched along with maintenance staff from Cardiff, including Vic Osborne. Through July and August of '87, the aircraft performed well but were under-powered during high and hot conditions with a big load onboard. The planes were used for loaded patrols and initial attack on hot spots, as they shined in this role as they carried massive amounts of fuel over 4 internal wing tanks giving it a loiter time pushing 7 to 8 hours. The Fieldmasters were responsible for extinguishing approximately 120 fires during their first season in France. A mid morning takeoff for patrols would usually have them airborne for 4-5 hours doing what was described as a lose pattern grid search at an altitude of about 5000 feet and cruising at 130 to 140 kts.

By the end of 1987, sales of the aircraft had been non-existent so Desmond leased them to various companies to bring in revenue and to test them in real world situations. 2 aircraft, NACN and NACM were leased to Agricair in Zimbabwe, Africa to spray for Tse Tse flies and worked alongside two Turbo Thrush aircraft spraying during the night at treetop height. The Fieldmasters had been outfitted with special navigaion equipment in the rear seat for the navigator and intense night lighting to light up the ground.

While NACM and NACN were working the Tse Tse fly contract in Somalia, Desmond decided to send NACL on a sales tour to Australia and then to Singapore for the airshow in January of 1988. Renowned female ferry pilot Janet Ferguson made the long trek to South Australia from Cardiff, Wales covering

some 9000 miles one way. Once Janet arrived safely in Australia, NAC`s second test pilot, Doug Barden, flew out on a commercial flight and then took CL to various Australian states showing off it's fire fighting capabilities. Australia was celebrating its bi-centennial so the aircraft was painted with a “Happy Birthday Australia” on the aft fuselage. After touring Australia, Janet flew the long trip back to the UK, stopping in Singapore along the way to participate in the Singapore International Airshow.

By the summer of 1988 the last two production Fieldmasters were completed. NACO & NACP were flight tested and ready to join the other three production aircraft. All five of the aircraft were essentially the same...Pratt & Whitney PT6A-34 turboprops at 750 hp, 625 US gallon titanium hoppers, dual seating and the rest of the innovations that Desmond had designed. There were minor variations between each aircraft but nothing major or significant. The layout was working well and all 5 aircraft went to France for the 1988 firefighting season in Cannes. This would be the only time all the Fieldmasters would work together in one location, minus the original prototype NRDC.

The firefighting season in the south of France was providing good information on the performance of the aircraft in its role there but still there were no orders for the Fieldmaster.

Leading up to 1988, Desmond came up with an agreement to have some Fieldmaster fuselages and wings be produced by Utva Aviation in Yugoslavia. The airframes would then be shipped back to Cardiff for final assembly. Utva found some issues with the wing root and redesigned it providing more strength to the main spar as well. They also redesigned the nose section to accept a 724 shp M601D-1 Walter Turboprop as a less expensive alternative to the pricey Pratt & Whitney. This project lasted until 1992 when war broke out in Yugoslavia and Utva was notified that it was under Western sanctions and work on the British airframes was to cease immediately. The Utva factory suffered severe damage during the war but miraculously the airframes survived unscathed and were put into storage till 1999.

In early fall of 1988, NAC was under serious financial constraints due to the massive amount of money that was spent in order to get to this point of production. On July 26, 1988 NAC went into receivership with Price-Waterhouse directing the company. Desmond was out at the company that bared his name, but NAC would continue to operate until a buyer for the company could be found or the assets liquidated. As the story goes, Desmond had his Freelance aircraft and the original Fieldmaster prototype NRDC moved out of Cardiff the morning the receivers arrived to take over. For some reason these aircraft were not to be part of the sale of the company and Desmond made sure they were not confiscated. Some of the workers were laid off while others were paid to merely show up, sweep the floors continuously and drink coffee. But only two months later, a former financial backer of Desmond purchased NAC's liquid assets and the rights to the Fieldmaster agricultural and firefighting aircraft, including the five production Fieldmasters.

Andrew MacKinnon and his company Croplease Ltd. began to plan on how to move forward with his new acquisition. However Andrew was not from the aviation world but rather the world of finance. He lived and worked in London while the aircraft were nowhere in his direct line of sight. All of the employees had been let go by this time but one engineer contacted Andrew and offered his services. It was at this point Vic Osborne became the sole engineer for the Fieldmaster aircraft.

After the 1988 summer firefighting ended in France, NACL, NACM and NACN were of f to Morocco in Northern Africa to spray for a massive locust infestation. They were based in Ouarzazate and once again Vic was there to keep the aircraft in tip top shape.

1989 started off slowly and NAC (now Croplease) had moved away from Cardiff to Bournemouth, UK and began to use Interair as a maintenance and parking facility as well as being their new home base of operations. The upcoming fire season was on the horizon and at the request of the French pilots, Croplease hired Brooklands Aerospace at Old Sarum to provide CAA M3 oversight for a planned engine upgrade from the -34 to the 1250 shp -65 Pratt & Whitney turboprop. The aircraft was designed to accept this upgrade from it's inception with new parts consisting of the engine, engine mount, five bladed propeller and a new nose cowling. The rest of the aircraft would remain untouched except for a gauge or two in the cockpit.

Vic Osborne and an assistant from Brooklands did the conversion in an old WW2 hangar at the Old Sarum airfield beginning in late August with the first flight coming on Oct 28, 1989. The first flight of the newly named Firemaster 65 was performed by British aviation legend Neville Duke with Vic riding shotgun in the rear. Duke's resume was legendary and his list of accomplishments and accolades is truly remarkable. He was a three tour veteran of WWII beginning his RAF career at 19 years of age in 1941 flying Spitfires from Biggin Hill over Europe. Duke was transferred to North Africa flying the Curtiss the P-40B Tomahawk and then the P-40D Kittyhawk. By September 1944, at the tender age of 22, he had amassed 27 victories in 486 sorties and 712 operational hours. He was flight commander by age 21 and squadron commander officer at 23.

After the war he became a RAF test pilot for Hawker in 1945 through 1948 and after retiring from the RAF joined Hawker again as their assistant chief test pilot until October 1956 when he was forced to retire due to injuries sustained in a few heavy and forced landings which fractured his spine leaving him immobile for months. His later life revolved mostly around civil aviation and his company, Duke Aviation, where he was a personal pilot for Sir George Dowty and a test pilot for the Edgley Optica and the Firemaster 65. He wrote several books about his life and experiences and his legacy has left a lifelong impression on those who met the man.

At this same time the original Fieldmaster NRDC was also at Old Sarum, and in late 1989 Vic was instructed to dismantle the airframe for some unknown reason. He removed the wings, engine, propeller and she sat there in that state till she was moved back to her ancestral home at the Sandown Airfield on the IOW on Nov 11, 1991. She was laid to rest beside Desmond's old hangar where she was born some ten years earlier. NRDC would remain there for the next 20 years along with the engineering sample and numerous parts. On Feb 14, 2011 NRDC and all the parts were loaded onto two trucks and shipped off to Jim Pearce who was a notable aircraft rescue and preservation specialist as well as being a former crop duster. Jim never got to restore the Fieldmaster and it was rumoured to again be sold to some brothers near Wainfleet, UK who had planned to open a crop dusting museum. That plan never materialized and it seemed as though NRDC was then lost and it became a sad note in the history of the Fieldmaster story. We will come back to NRDC later in this article.

Neville and Vic did the flight testing and -65 certification program from Sandown in early 1990 and all went according to plan with no issues to report except for the nose landing gear which now would flap from left to right from the prop-wash produced by the 5 bladed prop. They devised a simple fix by extending the nose wheel mud guard which cured the issue. Vic recalls this 3 week time spent with Neville as the most rewarding and treasured time in his own long and distinguished aviation career.

The Fieldmaster Resurrection Project can be contacted by the following outlets: Email: fieldmasterresurrectionproject@gmail.com

Facebook: https://www.facebook.com/groups/1483419635727874 or search for NDN/NAC Fieldmaster Resurrection

Phone or Text: 306-737-4212

Stay Tuned for part II of the Fieldmaster Aerial Firefighter story in the September/October issue of AerialFire Magazine