Unscheduled events are incidents that none of us want or need, but they do happen despite our best efforts. The maintenance manual contains a pretty big list of events that Pratt & Whitney Canada describes as unscheduled events. They cover everything from a prop strike to immersion in water. In this article, let’s look at some exceedances; specifically, we will look at over torque and over temperature.

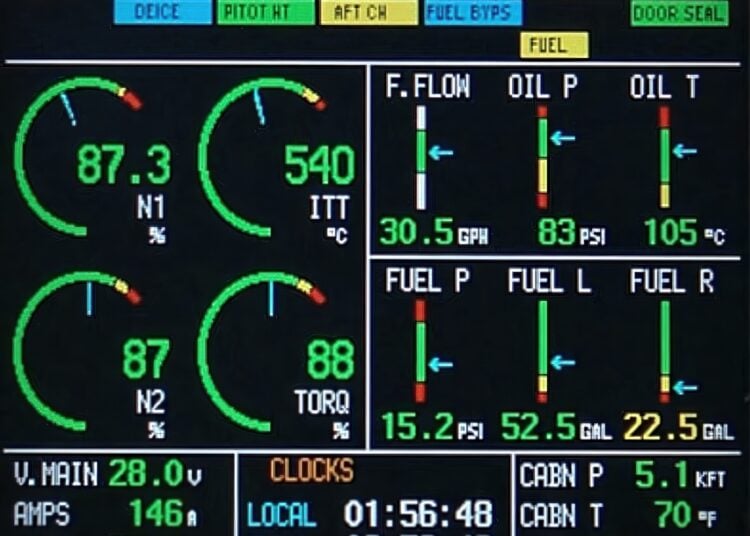

When either a temperature or torque event occurs, information is going to be key. Knowing the answer to the following questions is extremely important: How far above the redline? How long did it stay above redline? This information helps the engine shop determine the work scope required to return the engine to service. This is where the MVP-50T or any engine monitoring system comes in handy. Recorded data can be downloaded and provide accurate readings on exceedance and duration. When something outside the ordinary happens, the pilot can be busy; the most important thing is to get the airplane safely on the ground. That is why engine monitoring systems are a benefit to an operation.

You may be asked to complete a service information letter Gen-135 when one of these unscheduled events occurs. This is a form describing the circumstances of what occurred. If the engine is still under warranty, Pratt & Whitney Canada may also require a second form to be completed. Ask for help if needed; we always want to ensure you don’t inadvertently cause yourself struggles and pain by not crossing all the t’s. You can also visit about what needs to be done with your Pratt & Whitney Canada field service rep or C-First.

What is the first step if an over-temp event has occurred or is suspected? First, we must ensure the indicating system is functioning correctly. Make sure what the pilot witnessed was accurately reflected in the cockpit. Next, we must discuss the over-temp event. Critical components of this event are peak temperature and duration. The maintenance manual has a chart where you can line up the temperature and time, and the chart will provide the maintenance requirements. There is a limit where no action is required if the event occurs within the range. The next level is to determine and correct the cause of the overtemperature.

A visual engine inspection may also be a maintenance requirement after an over-temp. As temperature and duration go up, so does the level of maintenance. If it cannot be determined how long the event lasted or the peak temperature reached, then one must assume the worst case. Engine removal and engine shop visits are required for all Area C category events. When the temperature cannot be determined, you must indicate “Unknown Temperature” when sending the engine in for inspection. This is the signal to the engine shop on how to proceed. The inspection process can include destructive testing of at least two compressor turbine blades, followed by other inspection requirements in the PT6 manual. These actions are for over-temp events that are not at the start. If you have an exceedance of temperature on startup, there is a separate chart to determine what steps must be taken.

The maintenance manual also discusses inadvertent cut-off and relight of the engine during taxi. This is an event of its own and should be handled as stated in the maintenance manual. We have seen issues directly linked to inadvertent cut-off and relight, including failure of the compressor turbine blades. It is extremely important to follow the inspection criteria when such an event occurs.

Shifting the focus to over torque, like the over-temp event, there is a chart with the duration on one side and maximum torque reached on the other. Maintenance requirements are from no maintenance action to return the engine to the shop. If you fall between those categories, your engine has actions to monitor. First, we want to verify the indicating system is accurate. Next look at the oil system, we are looking for metal and debris in the oil. Rotate the propeller, listening for unusual noise. Pull the chip detector(s), oil strainers and the oil filter and look for debris. Per the maintenance manual, perform a ground run if everything looks and sounds normal. Ensure that nothing has changed in propeller operation, such as acceleration at the start or abrupt deceleration at shutdown. Run the engine to a specified power setting in the manual. Once the engine run is complete, pull filters, strainers, and detectors again to look for debris. Then, follow up on this same round of checks at the prescribed time in the future. For instance, we run the engine at 80% for 10 minutes in one manual and make our checks. Perform the checks again in one week/25 hours minimum.

Suppose you have an over-torque at the top of the chart that requires removal for inspection and servicing. You can be thankful that the PT6A has a modular design. You might be able to remove only the power section and send it in for repair rather than pulling the complete engine.

I always tell everyone to listen to your engine and watch for changes. The PT6A is a solid engine that will tell you when something is wrong. If you see something in your regular operation of the engine that strikes you as odd or different, ask about it. Talk to your mechanic about what is different; it may be nothing or an indication that something more dramatic could be coming. Finally, if you have an exceedance, don’t ignore it. Let’s all hope that we can avoid anything unscheduled.

Robert Craymer has worked on PT6A engines and PT6A-powered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and is an instructor of PT6A Maintenance and Familiarization courses for both pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member. Robert can be reached at robertc@covingtonaircraft.com or 662-910-9899. Visit us at covingtonaircraft.com.